RUSSELL CLAW

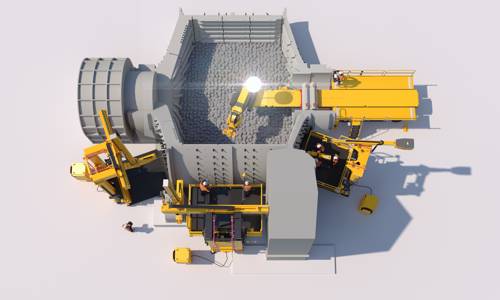

Introducing the RUSSELL Claw – the new master of muck-out and eliminator of manual liner slinging.

Lifting capacity up to 8000 kg.

When it comes to the muck-out phase of mill relining, the RUSSELL ClawTM grapple attachment for your RUSSELL Mill Relining Machine (MRM) is a serious piece of equipment. Tough, durable and strong, its powerful jaws will grab knocked-in worn liners from wherever they fall and deliver them to the liner cart for removal. But above all, safety is its first priority. The Claw reduces the number of crew needed inside the mill during the hazardous muck-out operation and eliminates the need for manual slinging.

BENEFITS

- Transforms risk and safety: eliminates the need for manual slinging of liners.

- Reduces confined space, suspended loads and mobile plant hazards for reline crews.

- Versatile: works with all feed, shell and discharge liner designs from leading OEMs

- High payload capacity: Lifts any liner up to 8000 kg.

- Superior toughness, durability and reliability.

- Requires less crew for liner removal, improves resource allocation to value-adding tasks.

- Improves RUSSELL MRM utilisation, efficiency and return on asset usage.

- Enables MRM operators to increase liner manipulation speed without risk to crew safety.

- Facilitates faster cycle times and reduced liner removal duration.

- Creates new opportunities to increase mill availability.

FEATURES

-

- Works with all feed shell and discharge liners without

requirements for design changes - High strength HARDOX tensile steel for superior toughness and wear resistance

- Incredibly rigid frame with three (3) hydraulically-powered moving jaws mounted

- Jaw fingers deliver a safe, secure and steady grip and constant closing force

- Integrated pry bar tool fitting to dislodge stuck liners off the mill shell

- Pry bar attachment is easy to insert utilise discarded grate liner bolts after knock-in

- Nonslip jaw slippers are easily replaceable

- 360° rotary actuator allows for easy pickup from the Grapple and Grapple Tool

- Fast and easy fitment: enters mill via the liner cart and installed by the grapple’s single use adaptor tool

- Fits both 2-pin and 4-pin RUSSELL MRM grapples

- Easy to learn and operate via the MRM controls

- Suitable for most RUSSELL 7 and 8* Mill Relining Machines 2500kg – 8000kg

- Can be shared between multiple MRMs onsite

- Comes with sturdy storage cradle for easy use on site

- RUSSELL ClawTM technology and processes are supported by RME’s proven operational readiness program and OEM-certified Customer Service Technicians

*Retrofits required for RUSSELL 7 and 8-axis MRMs pre-2023.

- Works with all feed shell and discharge liners without

-

- For mine sites seeking to transform risk and safety ratings and improve relining efficiency

- The RUSSELL ClawTM is intended for use during the muck-out phase of mill relining

- Enables fast, reliable, safe worn liner from the charge without

manual slinging - Part of RME INSIDEOUTTM Technologies tools and methods

which remove reline crew from inside the mill during hazardous

relining

RME is the world’s leading Original Equipment Manufacturer (OEM) of mill relining systems.

RUSSELL MRMs engineered, manufactured and delivered.

THUNDERBOLT Recoiless Hammers sold.

Mine sites served by RME equipment and services.

"The efficient RUSSELL ClawTM is the ultimate solution for muck-out. Its powerful jaws can quickly and effortlessly pick up worn liners and deposit them on to the MRM Linercart. But what sets it apart is its focus on safety. The Claw eliminates the dangerous task of manually slinging liners, which has long been a major hazard during the process of mill relining."

Related products

RUSSELL ALL REACH GRAPPLE

The new RUSSELL All-Reach Grapple manages heavy and deep liners effortlessly and tackles difficult mill conditions.

Read more

RUSSELL 7-R AUTOMOTION MRM

The world's first semi-automated mill relining machine for relining from outside of the mill.

Available in 4500 kg – 9000 kg capacities.

RUSSELL 7-S+ MRM

RME's signature 7-axis machine now future-proofed with AutoMotion-ready hardware.

Available in 4500 kg – 9000 kg capacities.

RUSSELL 7-S MRM

Signature performance and the industry’s most widely adopted mill relining machine.

Available in 2500 kg – 9000 kg capacities.

SS&O Sales Team

Matthew B. Thompson

Service Account Manager - APAC

Gary Medill

Service Account Manager - APAC

Denny Wisely

Vice President Sales & Business Development - North America

Samuel Mossaad

Service Account Manager - Canada

Lyle Hobbs

Service Account Manager - North America